In the last several years, Raincountry has found a special niche in the refrigeration market; fish hatchery incubator chilled water systems installed and maintained at Federal, State, and Native American hatcheries.

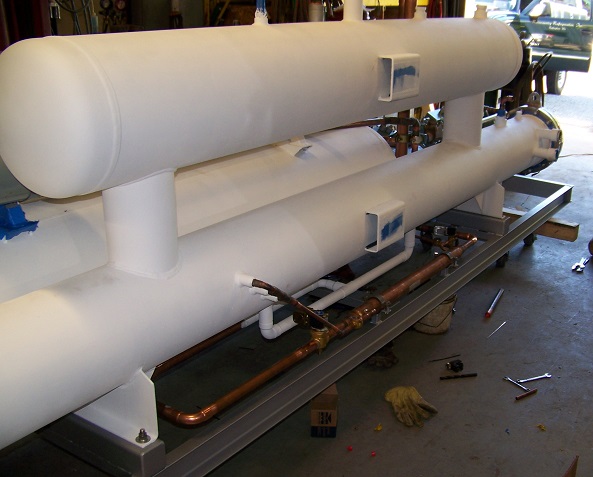

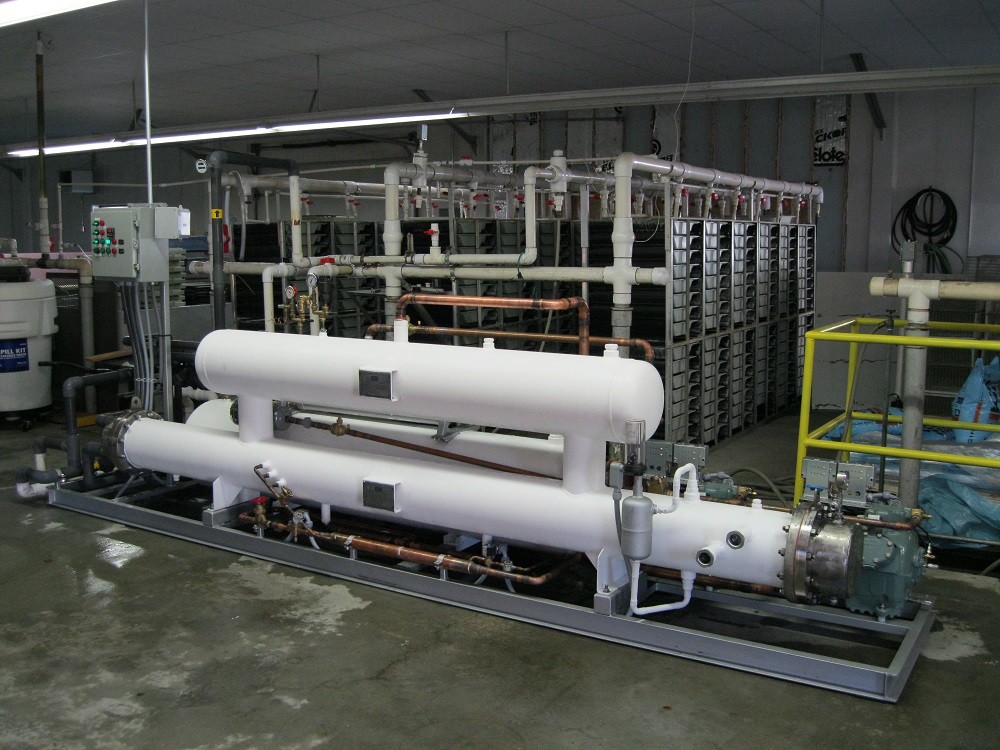

With either three-phase or single-phase electrical capability, these chiller systems are extremely flexible. They are designed to grow with your operation, ranging in size from 1.5 to 3000 GPM.

The systems are automated with Computer Process Controls (CPC) electronics, monitoring and controlling all functions. Built-in safeguards protect the equipment and most importantly, maintain stable incubator temperatures. Our exclusive CPC technology makes your chiller system “smart” and allows you to control, access, and minimize human error. (+/- 0.2° F)

By recovering heat and using recycled incubator water, as well as using state-of-the-art compressors, condensers, and plate and frame heat exchangers, a Raincountry chiller system helps you reduce your operating costs.

Through a team of highly trained technicians, Raincountry provides offsite and remote monitoring for your chiller systems. These same technicians offer on-going support, regular maintenance, upgrades, and specialized training for your entire staff.

Entiat, Washington

Hatchery

Cle Elum, Washington

Supplementation and Research Facility

Winthrop, Washington

Hatchery

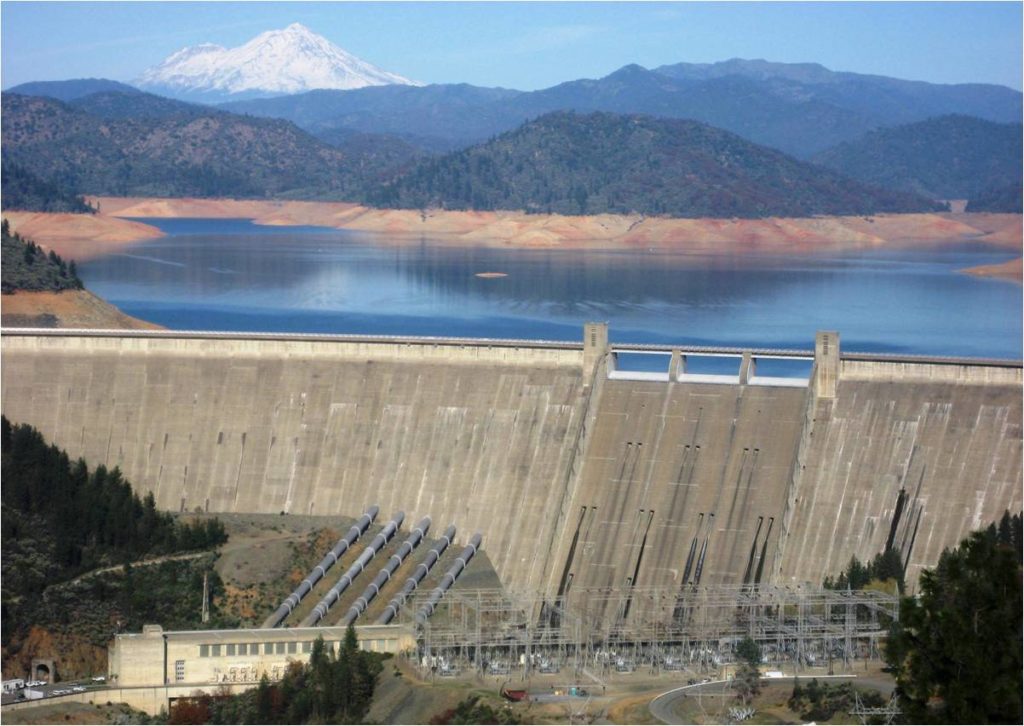

Shasta Dam, California

Livingston National Fish Hatchery